Effective, fully automated filtration technology for wet painting processes. RECLAIM system as a complete solution with two filter units.

Effective and energy-efficient. Filtration system suitable for 24-hour operation.

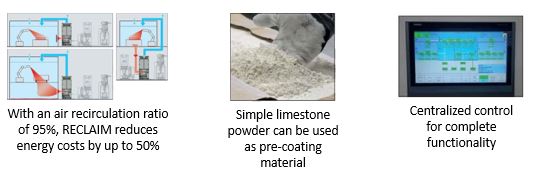

Modern painting system can be operated with significantly reduced energy usage by controlling the recirculate air supply between the overspray separation, the filter units, and the spray booth.

RECLAIM ensures that up to 95% of the purified and re-conditioned air can be recirculated into the spray booth.

*Only 5% ambient air is added to improve air quality.

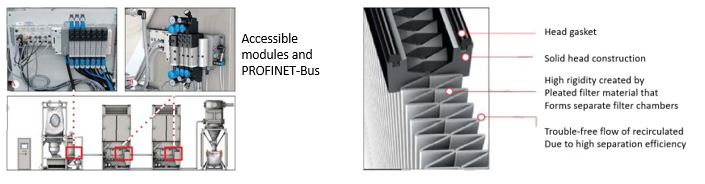

SIMATIC controller for systems and process control:

Parameterization and all function controls

Adding limestone powder to pre-coat the filters:

Limestone powder is added from a Big-Bag station. As an alternative, it can also be stored in a silo.

Dosing storage:

The dosing storage unit is equipped with a membrane pump and a fluidization device for continuous conveyance of limestone powder into the VARIO RECLAIM filter units.

Collection and ductwork:

Specific air-flow optimized solutions result in low accumulation of sediments inside the ductwork.

Filter unit VARIO RECLAIM:

The extracted overspray is separated by the dry operating filters. Up to 95% of the exhausted air can be reused for circulating air inside the spray booth.

Pre-coat treatment by “fluid rotor”:

Used and fresh limestone powder is loosened and fluidized. Due to the rotor effect, dry limestone particles rises inside the filter area and partially bonds over spray and aerosols.

Continuous, fully automated operation:

The illustrated structure ensures uninterrupted operation of the RECLAIM process.

Disposal system Big-Bag:

Disposal of the used pre-coat is carried out by exhausting the VARIO RECLAIM filter units. As an alternative, a silo can be used as disposal system for large quantities.

- RECLAIM system controller and disposal station Big-Bag

Overspray amount each week: 35 -300 kg - RECLAIM filter line of a recirculated air spray painting system

Designed for an air flow of 36 000 m3/h.

Dirty air volume: 10 mg/m3 up to 30 mg/m3. - Air flow: 86 000 m3/h Amount of overspray each

Dirty air load: up to 130 mg/m